Can You Put Gravel On Top Of Wet Cement For Decorative Surfaces

ane / 13

Pouring Concrete Mistakes

Near concrete projects fail because of avoidable errors in mixing or pouring. The harsher the winters where you live, the more important it is to steer clear of the kind of mistakes y'all'll larn about here. Poor physical techniques almost always lead to flaking, deterioration and premature failure. Avoid the top 12 concrete pouring mistakes and you'll have a project to be proud of for a long time.

2 / 13

Concrete Too Wet

This is probably the easiest concrete error to make because properly mixed concrete looks also dry to flow and trowel properly. Don't be fooled. Yous should be able to grade concrete into a 4-inch bore, four-inch tall pile if it's mixed properly. Any sloppier than this and the forcefulness of the concrete volition diminish.

3 / thirteen

Concrete Too Dry out

Although a less common problem than concrete also wet, too dry is not adept either. Portland cement is the active ingredient in physical, and cement needs sufficient moisture to cure with full strength. If troweling a sample pile of concrete doesn't create a polish, moisture, dingy surface in three strokes of the trowel, your physical is probably as well dry.

four / 13

Pouring Too Thin

Physical can be strong and long lasting, but only if it's thick enough. Are y'all pouring a concrete slab for a shed floor or DIY patio? This is the most common application for DIY physical pouring. Be sure you never make your slab thinner than iv inches for any application. Vi inches is the minimum thickness for a concrete slab that may see whatsoever kind of heavy vehicle traffic.

5 / 13

Expecting Reinforcing Mesh to End Nifty

No one wants a concrete projection to cleft, merely don't put your trust in the kind of standard welded wire mesh typically used for physical reinforcement. It won't stop cracking, but it will hold the cracked physical pieces together.

Mixing your concrete with reinforcing fibers and using reinforcing rods laid downwards on a 12-in. x 16-in. grid pattern greatly reduces the adventure of crack formation. Too, two weeks after pouring, utilise a masonry saw to make cuts one-third of the way through the thickness of your physical slab. Brand these cuts in a x-ft. x ten-ft. grid pattern. Any slight cracks that may form volition follow the saw cuts and exist hidden by them.

vi / thirteen

Using Old Cement

Portland cement, the agile ingredient in concrete, is a perishable commodity. Never use cement or a merely-add-h2o concrete mix that's more than a twelvemonth old for any project you care about. Even new cement with hard lumps should not be used for physical. Difficult lumps bespeak the cement has gotten moist at some signal and lost some of its power to harden.

vii / 13

Failure to Apply Fibers

Too few DIYers know most physical reinforcing fibers. These thin, brusque strands of plastic add a lot of strength and cleft resistance to any kind of concrete project. Add a pint of fibers to each mixing drum load of concrete and mix as usual. The fibers spread out within the mix and assistance bind the hardened concrete together. They make a large deviation.

8 / 13

Corrosion-Prone Reinforcing Rod

Physical is strong in compression, but weak when any strength tries to pull it autonomously. This weakness in tension is why concrete is oft reinforced with metallic rods. The trouble is, most physical reinforcing rods are fabricated of bare steel that's decumbent to rust from water that sneaks into the concrete.

When steel rusts, it expands, causing the concrete to flake off and come apart under internal pressure. This is why corrosion-proof reinforcing rod should be used for long-term reliability of physical projects. Use epoxy-coated, galvanized or fiberglass rebar for all ground-level concrete slabs.

9 / 13

Troweling As well Soon/Too Late

Smoothing concrete with a trowel to give it a overnice surface before it hardens is chosen finishing, and this step has to happen at just the right fourth dimension.

Ideally, you want to finish concrete when the surface water has dried, but the physical is still soft and workable. Trowel concrete as well early and yous'll get even more surface water forming, leading to a concrete surface that volition flake and neglect in time. Trowel also late and you lot won't be able to create a shine surface considering information technology's no longer soft enough. The time to await before finishing varies depending on air temperature and how wet the concrete is to begin with.

10 / thirteen

Concrete-to-Skin Contact

The cement in concrete is highly alkaline, and that ways it tin can injure your skin. The tricky thing is, yous tin can become wet physical on your hands all mean solar day long and notice nothing until the end of the day. That's when red, painful areas of thin, dissolved or cracked skin shows up. Employ a trowel and shovel to handle moisture concrete. And to be safe, wear gloves.

11 / 13

Weak Concrete Mix

The most economical mode to obtain concrete is to mix your own from Portland cement, sand and crushed rock. This is considerably less expensive than buying simply-add-water concrete mix in numberless.

Just beware — if you mix your own, don't cheat yourself. The standard concrete recipe is one part cement, 2 parts sand and three parts clean crushed stone. Don't skimp. Crushed stone is filler, so don't use any more than the recipe calls for. In fact, use a little less stone proportionally if you have a hard time troweling a prissy, shine surface.

12 / thirteen

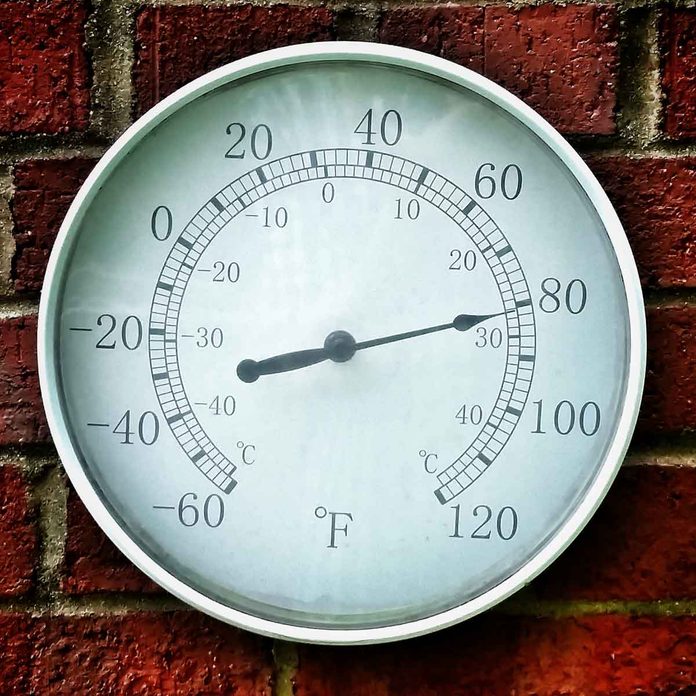

Wrong Air Temperature

This is one DIY to avoid when it'south hot and humid. Pouring concrete when information technology's hotter than eighty degrees F is risky because your physical tin begin hardening sooner than you can go it poured and troweled. Pouring concrete when at that place's danger of frost is besides a trouble because concrete loses a tremendous amount of strength if information technology freezes earlier curing. Moderate temperatures are e'er the best for pouring concrete.

13 / 13

Inaccurate or Weak Forming

A poured concrete projection is only as authentic as the forms that held the concrete while it was moisture. That's why information technology pays to check and double-cheque your forms before whatsoever pouring happens.

Forcefulness is another issue. Physical is really heavy stuff, and the taller your forms the stronger they demand to be. "If in doubt, build information technology stout" definitely applies to physical forms. A form that blows out during a concrete pour is a disaster, so employ lots of wood and braces when building your forms.

Originally Published: September 04, 2020

Source: https://www.familyhandyman.com/list/mistakes-pouring-concrete/

Posted by: gillsexion1976.blogspot.com

0 Response to "Can You Put Gravel On Top Of Wet Cement For Decorative Surfaces"

Post a Comment